Products

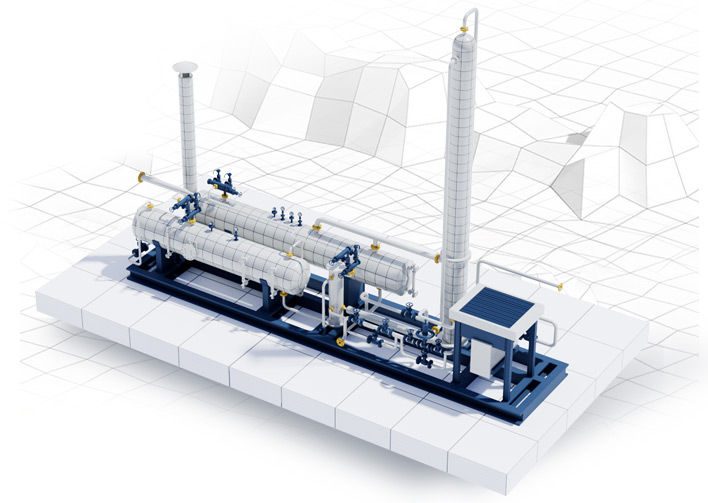

Gas Condensate Stabilization Unit

Main purpose of Condensate Stabilization Units (CSU) is to provide the required values of saturated vapor pressure by distillation of light fractions.

Stabilization of gas condensate by degassing or separation is based on reduction of solubility of low-boiling hydrocarbons in condensates at increased temperature and decreased pressure. When using stabilization units, the condensate yield is greater and the amount of waste gases is less than when using staged degassing.

3 methods are used for gas condensate stabilization:

- Staged weathering (separation, degassing)

- Fractionation in stabilization columns

- Combination of separation and fractionation

For condensate stabilization 1-, 2- and 3-stage degassing schemes can be used.

For any questions related to the equipment, please contact

tender@technotecs.ru-

- Comprehensive water conditioning solutions

- Water Treatment Stations. Water Treatment Plants

- Comprehensive waste water treatment solutions

- KOS-L Modular Storm Water Treatment Packages

- KOS-P Modular Industrial Water Treatment Packages

- KOS-B Modular Domestic Water Treatment Packages

- Membrane filter elements for reverse osmosis and ultrafiltration units