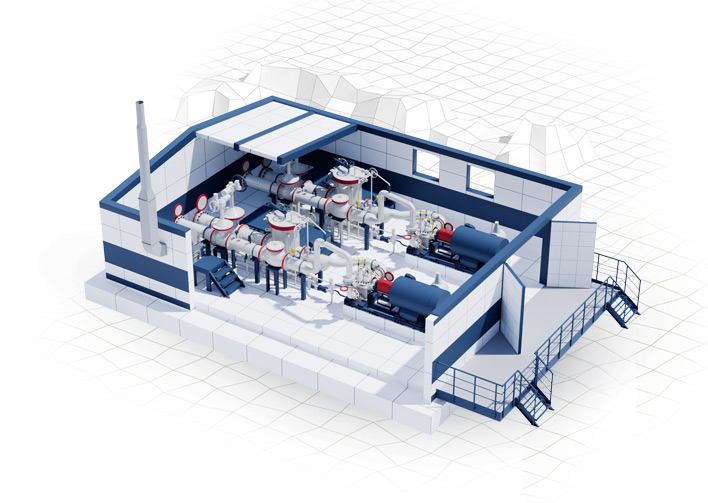

Water pump station is a packaged modular building mounted outdoors, dimensions of which are determined by the number and size of pump units. Water pump station consists of block-box, one or two (or more) pumps and process pipelines mounted in it. Usually, one pump is in operation, another is standby. Number of pumps is determined during engineering and development of technical specifications and can be adjusted.

Stations are delivered to the place of operation ready to be connected to the process pipelines and utility networks, which significantly reduces the time period required for putting the equipment into operation. Shelter units are equipped with electric or water heating system, lighting, ventilation, gas detection systems, fire alarm sensors and lifting mechanisms. Service platforms are provided for convenience of maintenance of pump units.

Steel structures are manufactured in accordance with all requirements. Load bearing structures and pipelines are subjected to anti-corrosion treatment. Level of automation of the station allows for its operation without constant presence of service personnel directly near the equipment and vessels.

Application

- Oil and gas extraction

- Oil refining, petrochemical and gas industry

- Metallurgy

- Refrigeration equipment

- Power industry, housing and utility infrastructure

Standard Scope of Equipment

— Pump unit:

- pump units with piping;

- supply and exhaust ventilation;

- waterproof lamps,

- racks with primary control devices;

- drainage system for discharging drained product into closed disposal system;

- heating system.

— Operator unit:

- internal equipment of operator unit;

- electrical panel;

- oil heaters with temperature regulator;

- monitoring and control cabinets;

- cable lines with control and power cables in separate metal boxes.

— Power- and electric supply unit:

- hardware unit;

- control unit;

- VSD unit;

- transformer unit;

- switchgear units;

- set of spare parts for commissioning;

- set of spare parts for 2 years of equipment operation;

- steel pipelines with flanged or quick-release couplings for units connection.

— Auxiliary vessel equipment

— Interconnect communication equipment

— Security and life support systems

Design features

- Packaged supply including low-voltage switchgear, MCC and operator unit. Power supply units and control units can be made both as single standing or combined into a complex under one roof with pump unit

- Process calculation of optimal piping diameters, development of efficient process schemes and application of energy-saving equipment, allowing to use the equipment in a wide range of supply flows and pressures

- Possibility of manufacturing mobile versions of water pump stations with installation on temporary foundations, skids or car chassis

- Structural design of block-boxes, foundation and frame of pump units can be expanded in case of increasing the capacity of water pump station

- Application of vibration compensation and thermal expansion in piping systems

Advantages

- Ergonomic equipment layout for efficient maintenance and repair

- Guarantees of trouble-free operation during the warranty period and the entire declared period of operation

- Fully automated control system that allows operation without presence of service personnel

- Technical consulting support during operation of pump station equipment

- Equipping pump stations with alarm, control and metering devices together with software that ensures trouble-free operation

Technical characteristics

|

Type of pump station

|

Capacity of one pump, m3/h

|

Head, m

|

Dimensions, mm

|

Maximum weight, kg

|

|

length

|

width

|

height

|

|

SNBV-13-70…350

|

11-15

|

70-350

|

6000

|

3000

|

4000

|

6000

|

|

SNBV-38-44…220

|

28-48

|

44-220

|

6000

|

3000

|

4000

|

8300

|

|

SNBV-60-66…330

|

48-80

|

66-330

|

6000

|

3000

|

4000

|

8500

|

|

SNBV-105-98…490

|

82-132

|

98-490

|

9000

|

3000

|

4000

|

9500

|

|

SNBV-180-85…425

|

87-220

|

85-425

|

9000

|

3000

|

4000

|

14000

|

|

SNBV-300-120…700

|

148-360

|

120-700

|

9000

|

3000

|

4000

|

16500

|

It is allowed to use pump units with other characteristics at Client’s request

|

Parameter

|

Value

|

|

Pumped fluid

|

Waste water, treated process water

|

|

Fluid temperature at pump inlet, °С

|

+5…+70

|

|

Density of pumped fluid, kg/m3

|

from 1000 to 1180

|

|

Maximum concentration of solid particles, %

|

0,1

|

|

Size of solid particles, mm

|

0,1...0,2

|

|

Climatic type

|

У/УХЛ/ХЛ

|

|

Fire- and explosion hazard category of the room as per NPB 105-95

|

А, Д

|

|

Fire Resistance Rating

|

I, II

|

|

Design air temperature, °С

- in control unit

- in other units

|

minimum +18

minimum +5

|

|

Service life, minimum, years

|

20

|