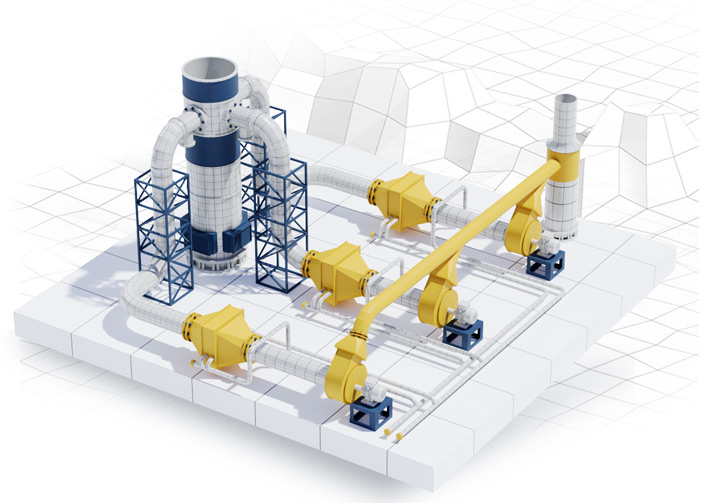

Working Fluid Heating Unit

Working Fluid Heating Unit is used at the sites of oil and gas fields to ensure the process of increasing working fluid temperature.

Various process fluids can be used as an agent (produced water, process water for heating, water-oil emulsion).

Working fluid is heated in the free-standing heat exchanger.

Flue gases generated during combustion of gas flow in a free-standing vertical chamber are used as heat transfer agent.

Main burners where the gas flow is ignited are located in the lower part of combustion chamber.

Flue gases are supplied to the heat exchanger through the gas duct by means of the fan provided by design. Flue gases not used for heating escape through the upper part of the chamber into the atmosphere due to natural draught.

Depending on the design, unit can include one or more heat exchangers. Herewith, fluids with different properties can be heated on each of them.

Standard Scope of System

- vertical chamber;

- main and pilot burners;

- heat exchanger and fan system;

- gas ducts;

- instrumentation and controls;

- stairs and service platforms;

- process control system.

Operation mode is autonomous, it does not require constant presence of personnel. Scope of supplied equipment includes the list of required instrumentation and isolation equipment to ensure proper operation of the system. Heating unit is developed individually based on the input data on the parameters of incinerated gas and heated fluid, and is intended for 24-hour and year-round operation.

Design features

Combustion of the entire range of discharges takes place inside a closed combustion chamber without visible flame and without impact of thermal radiation on the surrounding objects.

Design of Working Fluid Heating Unit allows to ensure low noise level, the lowest possible level of emissions into the atmosphere, as well as the possibility to control and perform maintenance of the critical unit elements (burners, instrumentation, isolation and control valves) without shutting it down for repair.

Advantages

- Involvement of flare gases in the technology process for heating the working fluid

- Smokeless incineration of discharges in a wide range of unit performance

- Low noise level

- Minimum level of emissions into the atmosphere

- No thermal radiation and visible flame

- Possibility of placing the unit near other production facilities

- Possibility of unit maintenance without stopping it and shutting down for repair