Products

NGL metering station

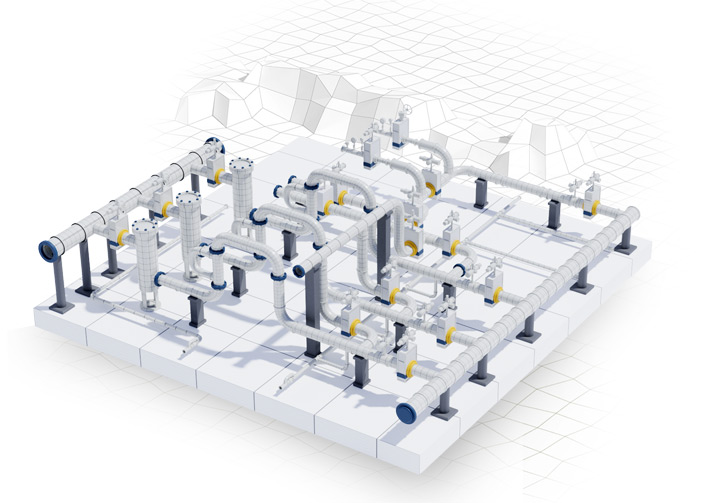

NGL metering station is designed for direct or indirect dynamic measurements of weight and product parameters. It is a set of measuring instruments, information processing systems, process equipment and other technical means located at different points of the controlled facility, functioning as a single whole and intended to obtain information about the measured parameters of the product and measurement conditions, automatic and manual processing of measurement results, indication and registration of measurement results and the results of their processing. When measuring product weight using dynamic methods, product in the pipeline shall be in a single-phase liquid state.

For any questions related to the equipment, please contact

tender@technotecs.ru-

- Comprehensive water conditioning solutions

- Water Treatment Stations. Water Treatment Plants

- Comprehensive waste water treatment solutions

- KOS-L Modular Storm Water Treatment Packages

- KOS-P Modular Industrial Water Treatment Packages

- KOS-B Modular Domestic Water Treatment Packages

- Membrane filter elements for reverse osmosis and ultrafiltration units